Harvested wood products store carbon, but the length of time that carbon is stored varies depending on a number of conditions. One of the most important factors is the type of product that the wood is used in. For example, wood used in construction material will store carbon for a longer period of time compared to wood used in pulp or paper products.

I’ve been presenting on harvested wood products and carbon storage recently. One question I’ve been asked on several occasions is why wood products in softwood species generally last longer than hardwoods. (To see how these longevities play out, explore this durable wood products calculator for more.)

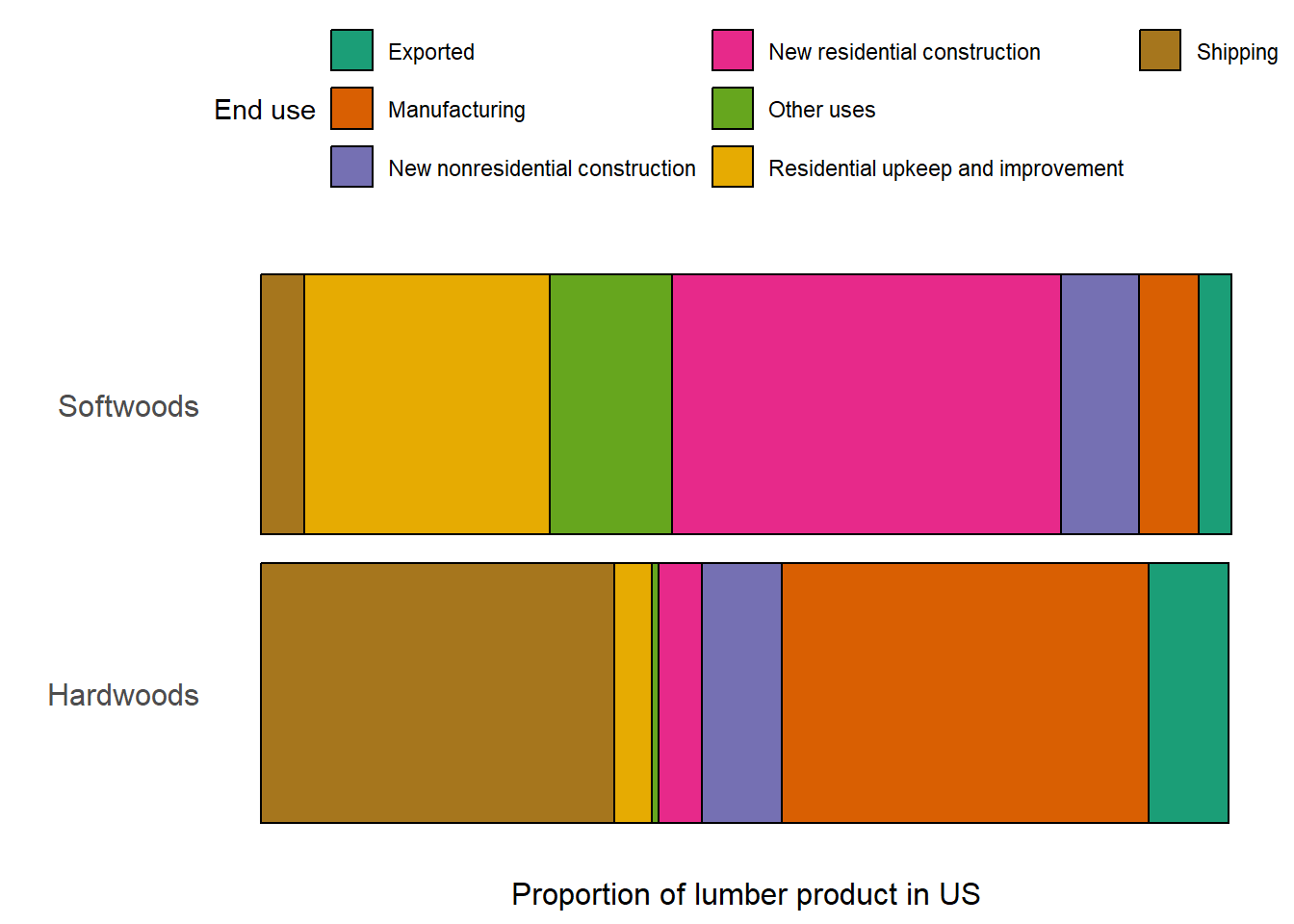

The short answer is that softwood species are generally used in end products that have longer lifespans. For example, softwoods are used in residential construction materials, including products like lumber and oriented strand board. These products are used in buildings and homes, where they can last for decades or even centuries. In contrast, hardwoods are often used in products like shipping, which have much shorter lifespans.

To show the differences in end uses for softwood and hardwood species, the figure below shows solid wood product production for various end uses in the lumber category. The data were presented in the McKeever 2002 publication and summarized in the Smith et al. 2006 (see their Table D2). The figure includes seven end product uses:

- New residential construction (including single family, multifamily, and mobile homes),

- Residential upkeep and improvement,

- New nonresidential construction (including railroad ties),

- Manufacturing (including furniture and other products),

- Shipping (including pallets and containers),

- Other uses (e.g., roof supports and DIY projects), and

- Exports

The data show that softwoods are used more frequently in new residential construction and manufacturing, while hardwoods are used more frequently in shipping and exported products:

In total, 66% of softwood lumber is used in new residential construction or residential upkeep and improvement, compared to just 8% of hardwood lumber in this category. In contrast, 36% of hardwood lumber is used in shipping, while only 4.5% of softwood lumber is used in this category.

This difference in end uses is one of the reasons why the carbon stored in wood products made with softwood species generally lasts longer than hardwood species. The longer lifespan of softwood products means that the carbon stored in these products is sequestered for a longer period of time, making them an important component of efforts to reduce carbon emissions and combat climate change.

–

By Matt Russell. For more, subscribe to my monthly email newsletter to stay ahead on data and analytics trends in the forest products industry.