I had the good fortune of taking a few classes from Dr. Bob Seymour while a graduate student at the University of Maine. Bob pioneered a lot of research in silviculture and ecological forestry that is being used in the region and globally. He has since retired, but is still active in the forestry community in Maine and beyond.

I saw a presentation from Bob last year where he described some harvests that occurred on his own property. He simulated the growth of the forest through time. These harvests occurred in diverse forests in Maine, ranging from mixed-woods to northern hardwoods and ash-dominated stands.

One of the principles mentioned in Bob’s presentation was the carbon recovery time, that is, the amount of time until a harvested stand exceeds its pre-harvest carbon stocks. The represents the amount of time it would take for a stand to “recover” from the harvest. The type (e.g., shelterwood versus clearcut) and intensity of harvest play an important role in determining the carbon recovery time.

In the kinds of forests Bob was managing, retaining trees during harvests and ensuring advance regeneration was present were two primary determinants that led to a shorter carbon recovery time. Even-aged management practices conducted over large areas would lead to a much longer carbon recovery time.

To show this, I simulate a mixed-wood forest stand from western Maine using the Forest Vegetation Simulator. The stand was measured in 2023 and had a basal area of 185 sq ft/ac. The stand was comprised of mostly red spruce (68% of basal area) and paper birch (10% of basal area) with lesser amounts of balsam fir, red maple, and yellow birch.

Two scenarios were run: * a non-harvested stand and * a commercial thinning where 40% of the basal area was removed from throughout the diameter range.

The stands were run for 50 years and the carbon recovery times were calculated.

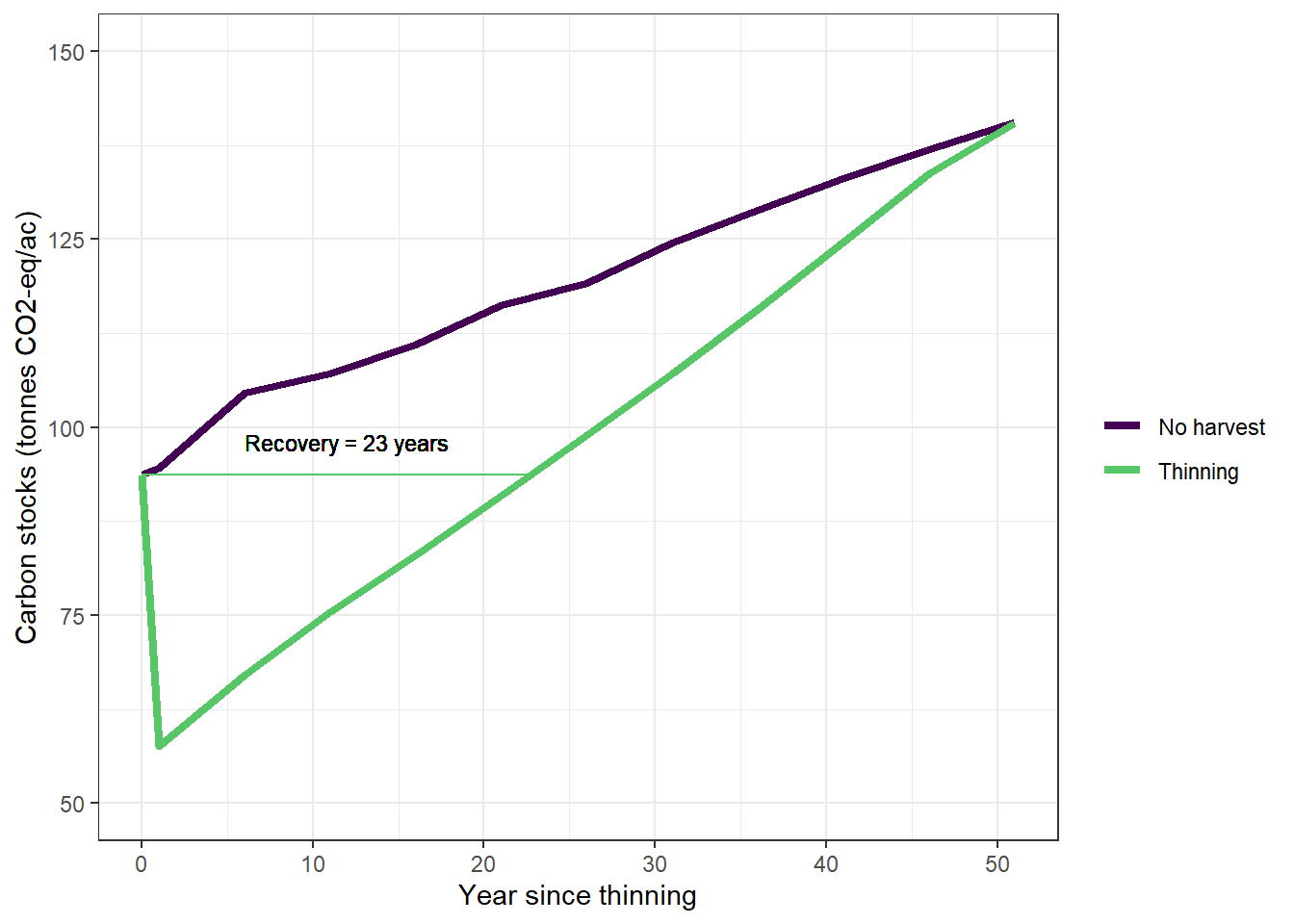

The graph below shows the carbon stocks of the aboveground biomass pool throughout a 50-year simulation. The stands began at 93.7 tonnes of CO2-eq/ac, with the non-harvested and thinned stands ending at 140.6 and 140.4 tonnes CO2-eq/ac, respectively, after 50 years. It would take 23 years for the thinned stand to exceed the pre-harvest carbon stocks in the stand:

If we only focused on what happened within the boundaries of the forest stand, this would be an important value for our forest managers and silviculturists to use in future planning. But because this was a commercial thinning treatment, we know that a portion of the wood harvested went into wood products, which will continue to store carbon into the future. In this stand, the larger diameter spruce trees would likely end up as softwood lumber (a product that has a slow decay relative to other products and species) and the smaller diameter mixed hardwoods would likely end up as paper or other shorter-lived forest products.

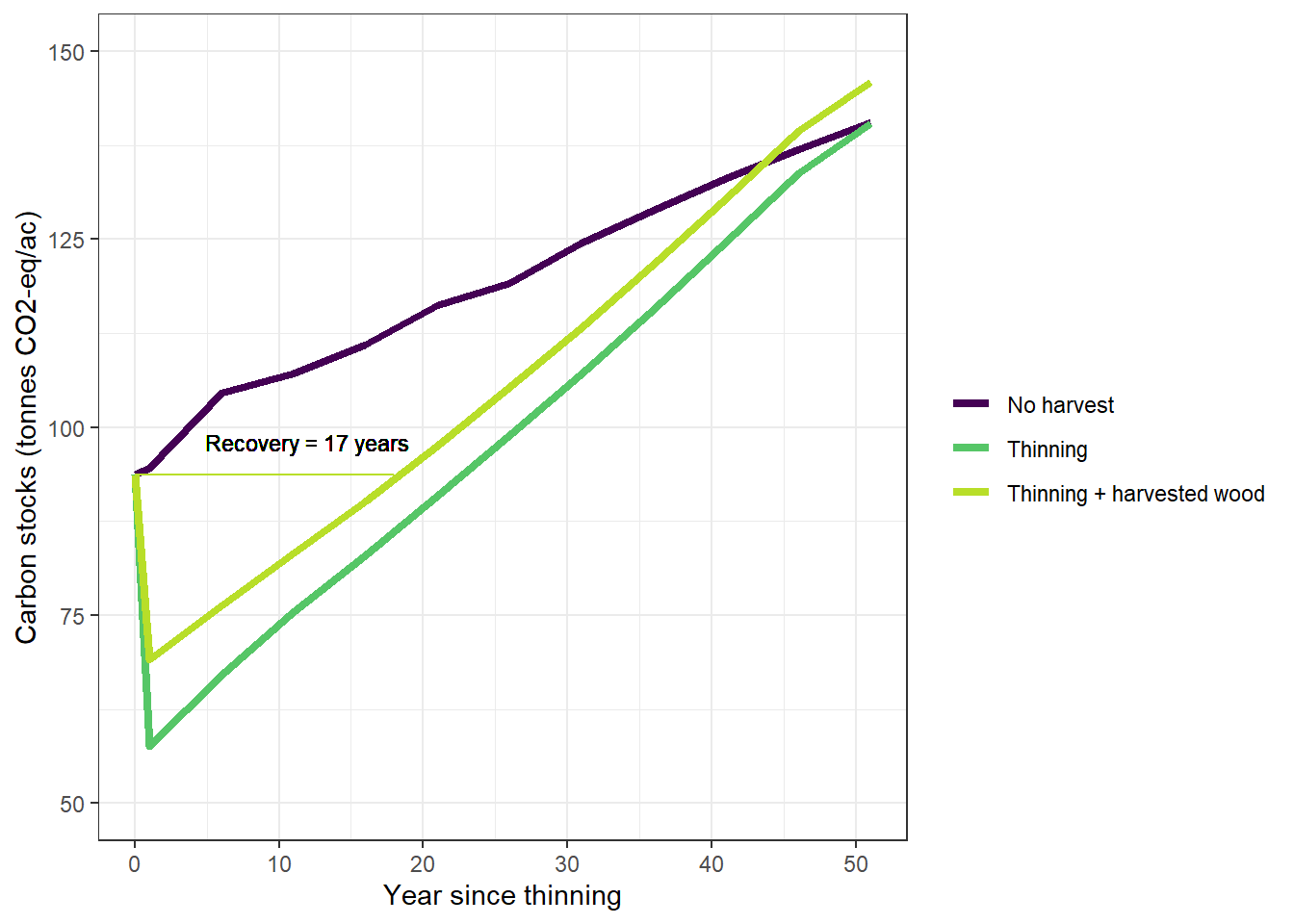

This harvest removed 36.2 tonnes CO2-eq/ac in the forest. The simulations transferred 57% of that amount (20.6 tonnes CO2-eq/ac) to the harvested wood products pool. All of this carbon was immediately transferred to harvested wood products in use, and then decayed either to landfills or were emitted as they decayed through time.

If we include the harvested wood products pool (in use and in landfills), the result is a shorter carbon recovery time. In this case, 17 years:

This exercise shows the importance of understanding the temporal component of timber harvesting if carbon stocks are a management goal. Most uneven-aged silvicultural treatments with lower harvest intensities will result in shorter carbon recovery times compared to even-aged management treatments that reset a stand’s age to zero. Note that I state that this is an important consideration if carbon stocks are the management goal - carbon sequestration levels can be greatest in young, growing stands.

It’s essential also to include the harvested wood products pool in these calculations. All too often managers look only in the forest to understand the effects of a timber harvest on the resulting stand. In our world where all carbon from trees and forests matters, whether the carbon is in the forest or in a wood product, let’s count all the carbon.

This example uses a timber harvest as an example, but the same principle would apply if trying to understand the impacts of a forest disturbance on carbon storage. Carbon recovery times could also be used to weigh alternative management scenarios for at-risk forests.

For example, a forest manager may concerned with maintaining the productivity of their ash forests with the impending threat of emerald ash borer (EAB) in many areas of the US. The EAB is anticipated to lead to mortality of all ash species, and has in many areas of the US Lake States and Midwest. The management goal may be to keep these ash forested wetlands dominated by non-ash species and under a continuous cover. With this approach, the aim may be to keep the carbon recovery time as short as possible to ensure the forested areas remain forested and do not transition to non-forested swamps.

From a modeling perspective, this exercise would be more nuanced. Several management scenarios may need to be evaluated, such as whether or not to pre-salvage or salvage wood at risk of EAB, underplant with other species, or use other silvicultural techniques. Another consideration is whether or not the wood will be used in forest products (i.e., is salvaged) or if it will remain in the stand following the disturbance and left to decay as standing dead trees and eventually downed dead wood. All of these are just a few of the considerations to understand the stand’s recovery following a disturbance.

–

By Matt Russell. For more, subscribe to my monthly email newsletter to stay ahead on data and analytics trends in the forest products industry.